Esko (www.esko.com) will showcase the design-to-print-to-cut savings made possible by improved automation with the UK’s first demonstration of i-cut Automate at Sign and Digital UK 2012. Also on show will be the extensive i-cut Suite of integrated software solutions and a Kongsberg i-XP24 digital finishing table. Esko is located on stand J32. Sign and Digital UK takes place at the Birmingham NEC event between March 27-29.

Paul Bates, Esko’s Regional Business Manager UK & Eire comments: “Every production element, from time to waste, is now under careful scrutiny as companies seek to make savings in every corner of their operation. As a result, they are readily realizing the benefits of the quick and easy addition of simple software enhancements that can dramatically improve throughput while minimizing errors. This helps make a tangible difference to their bottom line and can also help foster stronger customer relationships – crucial in an economic climate when holding onto business already won is so important.”

Building dynamic workflows

Built on Esko's highly successful Automation Engine, i-cut Automate is the latest addition to the i-cut Suite collection of pre-production software targeted at users of large format digital printers and/or digital finishing systems. i-cut Suite is built on the company’s extensive experience with advanced pre-production and workflow solutions in packaging and commercial printing. Its modular approach provides a rich toolkit to deliver sign and display products with optimal efficiency and productivity.

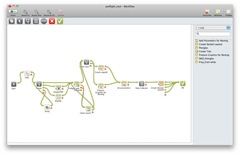

Tying the pieces of the i-cut Suite together, i-cut Automate automates the entire production process, from design-to-print-to-cut so users can build dynamic workflows that will automate repetitive prepress tasks. It enables i-cut Preflight, i-cut Layout and i-cut Vision Pro tools to run in a single automated workflow, minimising operator intervention and the potential for manual errors. Through Mac or PC based clients, operators can easily monitor the workflow and interact when necessary through a comprehensive checkpoint.

All these repetitive tasks can be made far less time-consuming through setting up dynamic workflows that are easy to operate in a client-server environment. i-cut Automate can also be integrated with Management Information Systems, enabling automatic job creation and the submission of job parameters to the workflow via XML data. The result is enhanced productivity, reduced operator intervention and errors, and valuable time, money and material savings.

Continuous cutting for smooth production

Also on show will be the Kongsberg i-XP 24. Designed to operate continuously in a 24/7 production environment, the world’s fastest digital cutter is the best-selling Kongsberg system among sign and display companies. The workhorse of the Kongsberg series offers a comprehensive digital finishing solution for the widest range of materials, providing automation, high productivity and outstanding precision. The Kongsberg i-XP24 comes with the i-cut Vision Pro control system for accurate die-less cutting and perfect registration.

Visitors will also be able to see the table in a live production environment as it cuts a banner printed and finished by show partner Revolutions and Solent Sewing & Welding Machines respectively.

Comments

Post a Comment