Key decision makers from across Europe learned how Kodak’s combination of continually evolving technology and knowledgeable expertise could help them identify a clearer path to profitability at Hunkeler Innovationdays 2013 in Lucerne last week.

“What was important about this vibrant event for us was the ability to have so many interesting and engaging conversations with current and potential customers and decision-makers,” comments Philip Cullimore, Managing Director, Consumer and Commercial businesses EAMER and Chairman Eastman Kodak Sarl. “We know how rapidly our portfolio of solutions has expanded and evolved in the past year to 18 months and it is very exciting to be able to discuss this with the businesses they have been designed to help.”

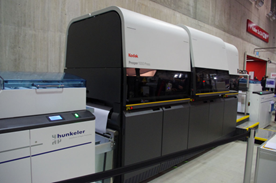

The next step in the evolution of the KODAK PROSPER Press Platform was announced at the show- the KODAK PROSPER 5000XLi Press, upgradable from the 5000XL Press. It features Kodak’s new Intelligent Print System (IPS) that monitors output quality and makes adjustments on the fly. IPS enables the PROSPER 5000XLi Press to learn from the input and calculate imaging improvements to deliver high levels of print quality and productivity. There are also the optional Image Optimization Station (IOS) that provides an in-line aqueous coating for the use of commodity papers instead of more expensive inkjet-treated offerings, the custom-formulated nano-particulate inks, multiple paper paths, and text enhancement technology, while uptime is aided by innovations in the transport system.

“Visitors were excited to learn about how the new KODAK PROSPER 5000XLi Press widens the profit pool of pages available for inkjet print production by producing high quality on a wide choice of papers,” says Will Mansfield, Kodak’s Director of Marketing, Inkjet Printing Solutions. “With KODAK Stream Inkjet Technology providing a 30% wider color gamut than offset, we’re seeing more work migrating from traditional processes to digital production and that’s driving profitable growth for our customers.”

Also highlighted was the performance possibilities of the KODAK PROSPER 1000 Press that produced black and white trade and educational books with a HUNKELER Finishing Line. One of the most productive inkjet web presses for 8, 12 and 16 page signatures with a duty cycle of 90 million A4 impressions a month, the compact, monochrome, 200mpm PROSPER 1000 Press offers one over one perfecting and is capable of print quality up to 175lpi on uncoated substrates ranging from 45g/m2 to 175g/m2.

The growing demand for inkjet printing inline with offset printing resulted in the development of hybrid technology using PROSPER S-Series Imprinting Systems. Under the banner of ‘Digital Your Way’ - Kodak demonstrated how the hybrid technology of the KODAK PROSPER S5 Imprinting System with CMYK is ideal for retail and direct mail applications. Running at 152mpm and with high image quality, it lowers the entry point into hybrid printing and is fully field-upgradable so customers can increase their capabilities when demand requires. The benefits of inkjet printing inline with offset printing include faster job turnaround time, lower costs and higher productivity for imprinting applications when compared to roll-fed laser printing. It also eliminates drying time and enables imprinting on the sheets as they pass through the offset press, saving up to two days in production time.

Showcased, too, was the KODAK NEXPRESS Digital Production Color Press with its field upgradable enhancements such as a turbo* mode capability that combines high-quality digital color production with peak productivity and a Long Sheet option for larger applications, including point of sale, book covers, dust jackets, packaging inserts and labels.

The Intelligent Calibration Solution (ICS) version 3 software, a unique element in the Print Genius suite of productivity and quality control tools for the KODAK NEXPRESS Platform, enables a 20 percent faster processing time. The creative possibilities of the KODAK NEXPRESS Fifth Imaging Unit Solutions which enable spot colors, digital embossing, spot glossing, gold* and pearlescent* effects were also shown.

In fact, the industry's need for highly flexible cost-effective print production solutions and how they can help with the growth of digital printing was among the topics discussed at the fifth DOXNET. Kodak participated too in the book Interquest forum that featured Kodak customers Erick Piton, Director of Business Development, Nouvelle Imprimerie Laballery and Raimo Pollari, Pilot Plant Director at KCL discussing their digital print experiences.

“Hunkeler Innovationdays 2013 was a very successful event for us and we had many fruitful conversations that we expect to follow up on in the coming months. It was reassuring to see such an interest around what is to become a key date in any proactive digital printer's diary. We look forward to seeing you in Lucerne in 2015,” concludes Cullimore.

*technology demonstrations, not yet commercially available

About Commercial Imaging

Kodak’s Commercial Imaging business is driving innovation and change for customers in commercial, packaging and functional printing, and enterprise services markets. Kodak’s intelligent technologies and solutions provide customers greater competitive advantage and return on investment. For more information, visit graphics.kodak.com.

Comments

Post a Comment