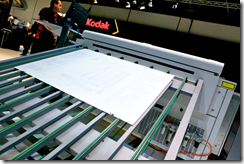

Just months after being made commercially available KODAK SONORA XP Process Free Plates are fast becoming the plate of choice for industry leading operations.

Launched at drupa, the plates won industry recognition with a stellar rating from Environmental Leader, a US daily trade publication focussing on energy, environmental and sustainability news. One judge wrote: “Being backed by a major company and likely useable widely, this is a neat solution to a present problem (a process with major impacts in terms of environment) that completely obviates the former technology.”

“SONORA XP Plates remove both the environmental impact and the cost of the processing chemistry, water and electricity that would normally be used during processing,” says Greg Batts, Kodak’s Sustainability Manager in Europe Africa & Middle East Region “These plates are being used in many countries around the world. Their sustainability advantages in reducing the costs and environmental impact are important here in Europe where Kodak customers are faced with rising energy and water costs. Kodak’s goal is to improve the sustainability of both their customers’ businesses and the printing industry as a whole.”

Among the printing operations already using SONORA XP Plates to maximum effect are general commercial printers Druckerei Aschenbrenner in Austria, Lasertryk.dk in Denmark, Maygray in the UK and leading French magazine printer Chevillon Imprimeur.

Sustainable operations with energy and cost savings

Druckerei Aschenbrenner GmbH switched to KODAK SONORA XP Process Free Plates to enhance its eco-conscious reputation. The FSC- and PEFC-certified sheet-fed offset printer was awarded the Austrian Eco-label in November 2011 and only uses eco-conscious print additives, mineral oil-free printing inks and water-based enhancement coatings.

“The new KODAK SONORA XP Plate means we no longer need a rinse unit or rinse solution,” explains Peter Aschenbrenner, Managing Director. “And we’re saving the energy that would be required for this rinse process. The new KODAK SONORA XP Process Free Plate is exactly what we’d expect from a modern, eco-conscious printing plate.” Druckerei Aschenbrenner even managed to reduce the laser power of the CTP system by 15 percent after making the change.

Lasertryk.dk also chose to raise its environmental credentials with a KODAK MAGNUS 800 QUANTUM Platesetter imaging KODAK SONORA XP Process Free Plates. Mads Bindslev, Pre-Press Manager at Lasertryk.dk says: “With the LOTEM Platesetter and the new MAGNUS 800 Platestetter working in harness we can achieve 80 plates per hour – 60 on the MAGNUS Platesetter and 20 on the LOTEM Platesetter. These production levels are changing our business and raising the bar.”

He continues: “There is of course the additional benefit of completely eliminating chemistry in an environmentally clean production space. By taking out the variable (the developer) in prepress, we have even better process control and can maintain stability and reliability in full plate production. We had to show our staff the benefits, but once they could see that the KODAK SONORA XP Plate is robust and reliable and works like any other plate, they are more than delighted with the results. The transfer to the KODAK SONORA XP Process Free Plate has changed our working lives. We have all the advantages of higher productivity levels and amazing quality plates with the added bonus this technology brings us.”

Creating a perfect litho and digital mix for maximum productivity

Maygray chose the KODAK SONORA Process Free Plates for its litho presses as part of its strategy to offer the best litho and digital print mix.

Steve Evans, Operations Manager at Maygray, explains: “The new SONORA XP Plate is proving its worth in every respect – repeatability and reliability as well as eco-conscious.” The SONORA XP Plate lets Maygray skip the processing step when making plates, as well as completely eliminating the need for processing equipment and chemicals.

He adds: “In today’s fast moving business world it is important that we research and adopt the latest technology available and give our customers the competitive advantage. We have re-arranged our premises to accommodate both litho and digital printing and can offer a full service and control every job from start to finish in house. We are huge fans of Kodak's Technology.”

Simplified production leads to 20% gains

Chevillon Imprimeur is a keen adopter of innovative technology and they had chosen Kodak’s previous process free plates, KODAK THERMAL DIRECT Non Process Plates, because of the elimination of chemistry combined with simplified plate production. Dominique Haudiquet, General Manager of Chevillon Imprimeur comments: “We made the switch to SONORA XP Plates because of faster imaging speeds that would allow us to increase productivity. The combination of the SONORA XP Plates and the KODAK MAGNUS 800 Platesetter has enabled us to increase productivity by 15% to 20%.”

KODAK SONORA XP Process Free Plates offer enhancements in imaging speed, run lengths, and latent image contrast over Kodak’s previous process free technology, while providing similar productivity and print capability as mainstream processed thermal plates. They improve stability and consistency of print while removing both the environmental impact and cost of the processing chemistry, and water and electricity of processing. With the KODAK SONORA XP Process Free Plates, all costs and environmental impact associated with the life cycle of the processing equipment are eliminated.

Olivier Claude, General Manager for the Print Business in Europe Africa & Middle East Region and Vice President of the Commercial Business for Kodak EAMER comments: “We are delighted customers are clearly embracing KODAK SONORA XP Plates as a robust, process free solution that benefits both the environment and the bottom line. They are enjoying the benefits of the same resolution, reliability, accuracy, and repeatability as traditionally processed thermal plates, with improved stability and consistency of print due to the elimination of those unstable, hard-to-maintain processing systems.”

Comments

Post a Comment