Strong growth, lower operating costs, increased competitiveness and a broader portfolio of services. These are the highly tangible gains Kodak customers across Europe have made after investing in KODAK PROSPER S-Series Imprinting Systems.

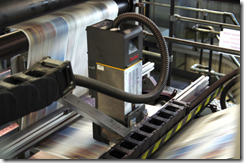

Building on Kodak’s innovative Stream Technology, the KODAK PROSPER S-Series Imprinting System is a hybrid solution enabling print service providers to produce offset class output in terms of quality, productivity and costs. Successful projects already executed by European printers include direct mail, inserts, games, advertisements and labels for packaging. Among them are German general commercial full service provider Kern GmbH, German media company Axel Springer, UK general commercial printer Anton Group, Spanish variable data specialist Mailfactory and Italian print service provider, Mediagraf SpA.

Lowering operating costs

Kern’s investment in six KODAK PROSPER S10 Imprinting Systems, to create a unique finishing line for variable data printing, has delivered strong growth and lower operating costs. It is designed for double-sided personalization and complete, rationalized finishing of self-mailers in one pass. One of the main reasons behind Kern’s decision to invest in the KODAK PROSPER S10 Imprinting Systems was the solution’s ability to handle a wide variety of uncoated, coated and glossy substrates.

The KODAK PROSPER S10 Imprinting Systems also allows Kern to work with standard offset ink set saving time and money. The company is also enjoying a significant productivity boost. “We now manage around 200,000 fully finished mailings per day—with laser imprinting, we could produce up to 40,000 items on a good day,” states Managing Partner Andre Kern. “We’ve virtually halved our personalization costs.”

Proactive personalisation that gets results

Axel Springer AG is using now a total of 33 KODAK PROSPER S30 Imprinting Systems on newspaper web offset presses at thirteen sites throughout Germany, including Axel Springer's own printing plants and designated contract printers. The systems are used to add personalized high quality digital inkjet printing content to offset-printers at a full production speed of up to 914 m / min (15 meters per second).

This is what German newspaper "BILD" capitalised on when it came to personalizing newspapers for a major Christmas lottery organized by BILD in northern Germany in December 2012. KODAK PROSPER S30 Imprinting System can also be used for editorial purposes – inserting targeted reader content, last minute stories or updates during production.

Delivering the variable data competitive edge

A total of 18 KODAK PROSPER S5 Imprinting Systems have been added to Anton Group’s portfolio, that also includes nine KODAK NEXPRESS Digital Production Color Presses. John Knight, CEO of the Anton Group says of the technology: “It is totally game changing and has raised the bar. There is a massive expectation from our customer base, and we can see more work coming our way. Waste savings are 20 percent on any one job, speed to market is mammoth, and it cuts out all other processes.

He continues: “Hybrid printing is the future, and I believe it’s here to stay. Our investments in digital production technology have played a significant role in our company’s growth in recent years and has taken us forward into the future.”

Developing a broader portfolio

Four KODAK PROSPER S5 Imprinting Systems have helped Mailfactory meet today’s market demands for variable-colour images at high speed. The investment, complementing six existing KODAK VERSAMARK Printheads, allows the company to increase competitiveness with a broader offering and more cost effective production costs. Today, Mailfactory exports a quarter of its production to other European Community countries and after investing in the KODAK PROSPER S5 Imprinting Systems, the company plans to increase this figure to 40%.

All ten KODAK Printheads are integrated with a single controller, so it can print black and colour at roll-feed speed. Now the company uses its new set-up to produce a range of documents, including personalised mail-outs, promotional literature, catalogue covers, and business and corporate collateral. “Customers are asking us for variable-colour images to help them win more contracts,” comments Mailfactory’s General Manager for Sales & Marketing, Eric Lahon. “We needed a solution that could deliver excellent quality at high speeds – and allow us to process our special finishes like scratch-off coatings, embossing, labelling and enveloping. We needed it to produce flawless images every time.”

Flying the hybrid flag

Mediagraf SpA’s investment in the KODAK PROSPER S20 Imprinting System has enabled the company to produce a wide variety of high-quality personalised print products, and establish itself as a valuable player in the marketing services chain, particularly with regard to the production of more targeted flyers and leaflets.

The KODAK PROSPER S20 Imprinting System was installed on a KBA Compacta 618 and Davide Dei Rossi, director of Industrial Activities at Mediagraf, says: “We needed a solution that wouldn’t adversely affect the web machine – the speed of the KODAK Printheads meets this requirement. We can print text, photos, bar codes and alphanumeric codes, QR codes, and more with excellent print quality on Mass & Food flyers, as well as self-covered magazines, editorial publications and a wide variety of print collateral using news, BC and LWC paper.”

Ahead of the competition

More than 400 KODAK PROSPER S-Series Imprinting Systems have been installed on six continents over the past three years. The family comprises the 500fpm S5, 1,000fpm S10, 2,000fpm S20 and 3000fpm S30.

The KODAK PROSPER S-Series Imprinting Systems lower the entry point into hybrid printing and enables a wide range of inline imprinted materials. These include personalized direct mail applications historically printed offline in a second pass using laser printers. This allows the production of jobs more quickly and more profitably. The systems are fully field upgradable and enables customers to increase their capabilities as their business grows.

Olivier Claude, General Manager for Print & Vice President Commercial Business EAMER Kodak comments: “It is great to see so many operations, from a range of sectors, enjoying the business-winning benefits of the retrofittable and flexible KODAK Printheads. They enable printers to make a big affordable difference to their product portfolio offerings by adding personalisation as and when it is needed. The ability to create a highly effective hybrid solution offers the speed of litho and the personalisation of digital helping businesses deliver a cost-effective digital and litho mix.”

Comments

Post a Comment