David Ho, Martin Automatic's general manager for the Asia-Pacific region, notes that the customer placed their order within a year after installing their first Martin splicer and rewinder. "This repeat order shows clearly the value of Martin roll-change equipment is highly appreciated. According to the end-user's calculation, the first MBSC and STR helped reduce their defect rate on that press by 2% and their material waste by over 1.6 tons in less than a year."

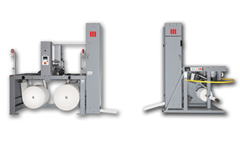

With a compact size, the MBSC and STR combination is a practical and affordable upgrade that significantly boosts productivity and reduces materials waste for more profitable operations. The MBSC and STR provide roll change automation for label presses with web widths to 330 mm and speeds to 150 m/min. For the Omet press, the new Martin equipment will provide non-stop roll production of substrates including paper, light tag, pressure-sensitive label and film stocks.

Source: Martin Automatic Inc.

Comments

Post a Comment