Demos & details how the partnership brings greater efficiency to label production scheduled at Labelexpo Europe 2013.

Esko (www.esko.com) and German leading supplier of die-cutting tools Wink Stanzwerkzeuge (www.wink.de) bring together their soft- and hardware expertise to create a highly-efficient staggered label solution. The combined solution enables label converters to optimize label production, increase production speeds, enjoy material savings and produce highly accurate print and die-cutting results. Both companies’ will highlight the benefits of this partnership at Labelexpo Europe, September 24-27 in Brussels, on Esko stand 5B25 and Wink stand 6G92.

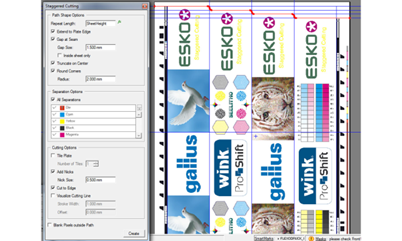

The partnership combines Wink's innovative die-cutting technology with Esko’s 'staggered cut' software and Esko Kongsberg cutting tables, resulting in the ProShift® technology. ProShift® enables impressions to be arranged more flexibly and make full use of the entire printing area. This is done using Wink's modern laser technology to arrange the upper and lower edge of the flexible dies in steps. Esko’s sheet layout software Plato creates the staggered label layout at the touch of a button. Perfect alignment between the printing and cutting plate is guaranteed, as the data is exported simultaneously to create the staggered flexo plate and to order the shifted die at Wink.

Shifting print to attain the advantage

“This type of shifted printing and die-cutting has many advantages,” explains Fransz Verbeek, Product Manager at Wink. “In most cases, labels are arranged symmetrically to save space and keep the consumption of materials to a minimum. However, this configuration is less beneficial for the rotary die-cutting process because vertical lines tend to cut more forcefully than horizontal lines and high contact pressure causes the vertical lines to cut even deeper. This can also damage the liner material and result in wear and lasting damage to all components in the cutting unit.”

ProShift® counteracts these negative effects by vertically shifting the impressions in the machine’s running direction, which significantly reduces the number of horizontal lines and evenly distributes cutting pressure.

Efficiency increased in prepress

When coupled with the tools in Esko’s Digital Flexo Suite, efficiency in producing printing plates and control processes is increased at the prepress stage. The software uses intelligent algorithms and is connected to Esko Kongsberg systems, so that plate cutting becomes fully automated. It also sets parameters for use when mounting plates to the printing cylinder.

“With the staggered labels solution conventional rectangular print shapes can be created on the cutting table as well as individually shaped and staggered images with accurate contours and consistent repeat accuracy," comments Pascal Thomas, Business Development Manager Flexo at Esko. "This means prepress companies can supply their customers with pre-cut flexographic printing plates ready for installation, saving time and costs. Automatic plate cutting also means that print companies can benefit from higher quality and more accurate cuts.”

Benefiting for staggering

The ProShift® solution has many advantages compared to conventional label production, particularly when cutting rectangles or other shapes with many horizontal lines: optimization of die-cutting results and reduced liner damage, longer lasting flexible dies and machine parts, stabile waste stripping which prevents web breaks and thus reduces down time, ... By using the ‘staggered cut’ option of Esko’s software and Kongsberg cutting tables, the advantages of shifting labels become clear for the printing part as well. In order to guarantee an efficient workflow for the label printer and coordinate the offsetting of printing blocks and flexible dies as accurately as possible, the relevant order data is simultaneously prepared and converted into digital format by Esko's Digital Flexo Suite.

Comments

Post a Comment