Kodak topped its successful packaging and labelling solutions showcase at a lively Labelexpo Europe 2013 with a distribution deal for KODAK FLEXCEL NX Systems in the Benelux region as well as with the announcement of significant industry partnerships and collaborations with The Uteco Group, BOBST and MPS..

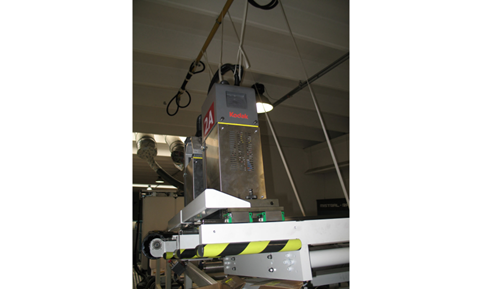

Leading the way in flexo packaging developments is the installation of two KODAK PROSPER S20 Imprinting Systems, one black and one color, on an 8-color UTECO ONYX 810 flexo printing system from flexible packaging printing press manufacturer The Uteco Group. With a print speed of 600mpm, fully in-line with the production speed of Uteco’s flexo printing machine, the KODAK PROSPER S-Series Imprinting System prints at a resolution of 600x300 dpi and a width of 10.56 cm. The integrated solution allows flexo printers to offer digital printing capabilities expanding the print possibilities offered by the combined technologies.

Leonardo Gobbi, Commercial and Marketing Director of The Uteco Group, explains, “The consumer goods market, both food and non-food, is increasingly driving packaging towards the realm of marketing and communication. The benefits of hybrid printing merge the flexibility and high productivity of flexographic printing with the unique capacity of digital printing to manage the variable data which customizes each individual print job and each individual packaging application.”

Flexible folding for creative packaging

It is flexible, folding carton and corrugated applications that will benefit from the strategic development agreement between long-standing collaborators Kodak and BOBST. Kodak has a broad range of technologies including KODAK Stream Inkjet Technology, color management, production workflow and digital front ends, as well as its general expertise in material and imaging science. Kodak is making this portfolio of technologies available for BOBST to utilize where it sees opportunities to add value to its products and solutions for the benefit of its customers.

BOBST is the world’s leading supplier of machinery and services to packaging manufacturers in the folding carton, corrugated board and flexible material industries. It is focused on creating the integrated solutions that enable the applications to come to life. Kodak is focused on the technologies that enable robust printing solutions for the packaging market. It has a broad range of technologies including KODAK Stream Inkjet Technology, color management, production workflow and digital front ends, as well as its general expertise in material and imaging science. Kodak is making this portfolio of technologies available for BOBST to utilize where it sees opportunities to add value to its products and solutions for the benefit of its customers.

Total solutions provider

Confirming a strong position in the packaging market was the reason for Belgian-based Plantin and Dutch-based Tetterode’s distribution agreement for the KODAK FLEXCEL NX System, “We’re now not just a total solutions supplier to the offset market, but also to the flexo market,” Plantin sales manager Davy Elsmoortel comments.

The KODAK FLEXCEL NX System was among the solutions on show at Labelexpo. It delivers consistent high quality thanks to unique KODAK SQUARESPOT Imaging Technology and high resolution imaging materials . KODAK FLEXCEL NX Plates enable flexo printers to drive efficiencies in their production process while achieving outstanding print quality.

Together with the KODAK SPOTLESS Flexographic Solution, the FLEXCEL NX System was creatively presented as enabling the next generation of flexo printing capabilities when Kodak, MPS and Reproflex 3 teamed up for an exclusive day of live presentations to show Labelexpo visitors how to ‘Do More With Less’. The hugely popular demonstrations highlighted how leading prepress and press technologies come together to deliver outstanding, consistent print quality at the lowest delivered cost, and how offset-like quality can cost effectively and efficiently be achieved with the use of fewer spot coiour inks in narrow web UV flexo.

Other solutions on show included the FLEXCEL Direct System demonstrating the latest advancements in direct laser engraving technology, and KODAK PRINERGY POWERPACK Workflow that delivers outstanding performance and reliability, along with best-in-class productivity, connectivity and automation for exceptional efficiency throughout the packaging production. It is also designed to be seamlessly integrated with all KODAK Unified Workflow Solutions, including KODAK PANDORA Step-and-Repeat Software, KODAK COLORFLOW Software and KODAK SPOTLESS Flexographic Solution.

Olivier Claude, General Manager for Print & Vice President Commercial Business EAMER, Kodak. “We were very encouraged by the quality of the visitors at the show, the levels of enquiries and the insightful conversations we had. It was clear that this lively sector is thriving and bustling with activity. As such we are delighted to have a broad portfolio of solutions that can provide the high quality, consistent, business winning results our customers need to help them meet the high expectations of brand owners and specifiers.

Comments

Post a Comment