Many of the printing presses in use today in the UV sheet-fed offset segment have to process a very wide range of substrates, from absorbent papers to non-absorbent films and foils. To achieve perfect results, then, it's necessary to frequently switch back and forth between various ink systems (UV paper inks/UV film inks). This often results in high storage costs, confusion and mix-ups between the ink systems and additional problems when washing press components and during startup due to repeated switching over of vehicle systems.

The hubergroup, one of the leading suppliers of UV offset inks to the packaging segment, has addressed this problem and developed a new, universal UV offset ink that is the first on the market to unite the properties of a range of different UV ink series – NewV maxX. By employing innovative vehicle technology, the hubergroup has succeeded in formulating these inks for use not only on paper and card stocks, but also on non-absorbent substrates.

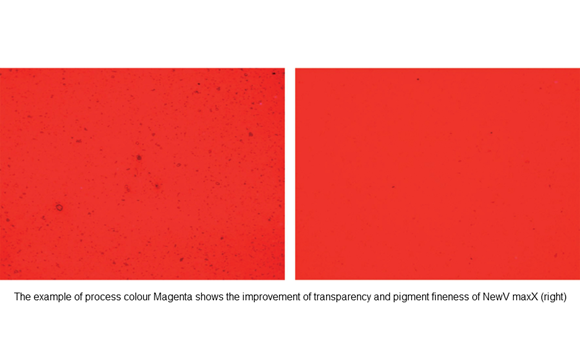

Excellent printability, optimum transfer, simple handling in the press and easy washup, combined with good dot definition, a composed finish and excellent wet-on-wet printing characteristics, characterise these inks. Thanks to the specially developed pigment technology developed in house, the inks offer a very high level of transparency and are therefore ideally suited to printing metallised papers and card stocks for cosmetics, perfume and spirits packaging. The adhesion properties on various plastic materials, such as PE, PS, PVC and PP, fully match those of a classic UV film ink. Prints produced with NewV maxX can be easily laminated and foil blocked. They can be coated inline or offline either with a water-based coating, such as ACRYLAC, or with a UV lacquer, such as NewV lac.

Compared with UV film inks for non-absorbent substrates, NewV maxX boasts greatly improved rub resistance. Its very good ink transfer and optimum wetting properties as well as the smooth finish it provides on non-absorbent substrates also qualifies this ink series for printing sleeves and wrap-round labels for glass and PET bottles on UV web offset and UV letterpress presses. Thanks to its ITX-, benzophenone and 4-methylbenzophenone-free formulation and very low-odour characteristics, NewV maxX meets all the requirements set for a state-of-the-art UV packaging and UV label ink.

In addition to process inks, the NewV maxX range includes basic PANTONE colours, CRS mixed colours and a special, very low-yellowing and highly opaque UV opaque white.

Comments

Post a Comment