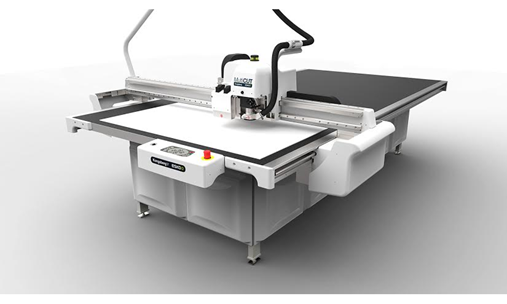

Entry-level digital cutting system offers the reliability, precision and ease of use Kongsberg tables are recognized for.

Esko (www.esko.com) announces that it has extended the world-leading family of Kongsberg digital finishing tables by introducing the new Kongsberg V series. Kongsberg V cutting tables deliver reliability, precision and ease of use for companies in the packaging and sign & display markets looking to complement their offerings with productive digital finishing. Built on the robustness of the Esko Kongsberg family, the new V series offers standard configurations for the best possible finishing quality of a highly diverse range of packaging and sign & display applications.

“The Kongsberg V series joins the well-known Esko Kongsberg X series and the recently launched large format C series platform,” says Marian Zincke, Esko VP Digital Finishing. “The launch of the V series extends our family of digital cutting solutions to make them accessible to companies who need an entry-level cutting solution but who do not want to compromise on quality, precision or reliability.”

Standard configurations ensure cost-effective cutting

The Esko Kongsberg V series is available in two standard configurations, each including the necessary tools to process market specific applications:

§ The Kongsberg V for sign & display comes with a MultiCUT tool head for vision controlled cutting and routing. The MultiCUT combines all tool insert options with an air-cooled milling spindle up to 45.000 RPM, perfect for a wide range of sign & display materials including acrylics and other synthetics. The camera system and innovative front-end software make it the perfect solution for production of lower volumes of signs and displays.

§ The Kongsberg V for packaging is specially configured for sample making, short run production of mockups and other packaging-specific applications. It is outfitted with a FlexiHead, which offers highly accurate, powerful cutting and creasing of packaging material such as folding carton and corrugated board. The FlexiHead is attached to a very precise servo axis controlling the tool depth when cutting, creasing and routing. Three configurable tool stations accommodate a full range of standard tool inserts.

“Esko began testing the market with this new family of cutting tables in Asia last year,” explains Marian Zincke, Vice President Digital Finishing. “Results clearly illustrated that there is a global need for a high-end digital finishing solution at an attractive entry-level price. That is exactly what the Kongsberg V brings. This unique platform is offered in sizes and standard configurations that have been designed to meet the most popular specifications according to our market research. We believe they are perfect for customers who want the productivity, reliability and precision that is characteristic of Esko Kongsberg machines, but only need it for specific applications.”

Rock-solid construction

The Kongsberg V series features the same rock-solid construction found in all Kongsberg tables, which makes them last for many production years. Kongsberg V is available in two sizes; V20 and V24, and is able to work on material with size1700x1300 mm / 66”x 51” (V20) and 1700x3200 / 66x126” (V24).

Kongsberg V cutting tables offer a broad selection of tools, providing quality results for a wide range of cutting, creasing, drilling and plotting activities. These new tables have many of the features that have made Kongsberg tables popular, such as the i-cut Vision Pro camera system for accurate print-to-cut registration even with print-distorted materials. Exchanging tools is quick and error-free because every insert is identified by a unique bar code and easily snaps into place. Insert knife tools are available for cutting materials ranging from thin paper and synthetic sheets to heavy-duty packaging and display materials. The rack-and-pinion drive system balances raw power with the finest axis control, ensuring speed, durability and strength.

Esko Kongsberg product family overview

§ Kongsberg C series: Large-format tables with high productivity, designed for finishing a mixture of 3,2m wide, flexible materials and demanding rigid material for sign, display and packaging applications. The C series is the first to combine wide format capability with high capacity output.

§ Kongsberg X series: the most comprehensive range of high-quality digital finishing platforms. It includes the smaller format Kongsberg XE for production of sign & display items or folding carton samples; the most versatile Kongsberg XN platform capable of handling heavy-duty finishing; and the Kongsberg XP for companies in need of continuous production. Even semi- or fully automated XP configurations are available.

§ Kongsberg V series: entry-level digital cutting solution with standard configurations for sign & display as well as packaging, ensuring high-quality finishing of a wide range of materials.

Kongsberg V finishing tables are available worldwide through Esko’s direct and indirect sales channels and will be on display during a number of industry events throughout 2014.

Comments

Post a Comment