Sustainability and environmental concerns are a key focus for FINAT and, of course, for the self-adhesive labelling industry as a whole, as part of the broader packaging business. This year’s FINAT Technical Seminar drew together different elements of the label value chain to address recycling initiatives in a discussion panel moderated by industry guru Mike Fairley. Panelists were Calvin Frost, Channeled Resources Group; Paolo Guagliumi, Munksjö; Erkki Nyberg, UPM Raflatac; Eric van Pottelbergh, RecuLiner; Stephan Reis, Avery Dennison, and Petri Tani, C4G.

Mike Fairley opened the session by reminding seminar participants that the very first patent for paper recycling was granted in 1800 – for newsprint. What, then, should restrain the label industry’s efforts to create a second life for spent release liner?

Pathways, today and tomorrow

Discussion was wide-ranging, across a number of important pathways in which the industry is already a participant, or which offer possibilities for recycling or re-use. Calvin Frost and Petri Tani agreed that one way forward is for the labelstock laminators to create the demand for secondary fibre, and communicate it to their suppliers. But, although such materials are available on the market, there is still no ‘pull through’ from the brand owners – perhaps, as Stephan Reis commented, because they may have to be willing to pay more for recycled material – which is rarely the case in today’s competitive marketplace. But, added Petri Tani, ‘even end users understand that recycling is better than landfill and incineration!’

Needed – a coherent message

Mike Fairley underlined the importance of the sustainability agenda for the future health of the label industry. ‘We are not getting the message across to the brand owners and end users,’ he said, ‘and we still don’t have a system for creating a carbon footprint through the label supply chain. As an industry, we simply don’t have one clear, coherent message.’

Liner recycling options

Closed-loop, cradle-to-cradle recycling is, naturally, a prime goal for FINAT members. In that context it is so much easier, and more successful, to set up recycling initiatives for film liner, because of its intrinsic financial value. Mitsubishi Polyester Film’s scheme for collection and recycling into their Reprocess™ liner programme – containing 25% of recycled material – is now handling 4-5000 tonnes per annum in the US.

Most of the negative recycling issues, sadly, relate to paper liner base. Paolo Guagliumi observed that it is helpful that paper liner is listed as ‘recyclable’ in the 2013 revision of EN 643. In this document, paper release liner for self-adhesive labels has been added to Group 5 (special grades) – as grade no. 5.05.03. (CEPI’s new guidance document -- http://www.cepi.org/en643 -- provides valuable detail).

Is release liner packaging or process waste?

If, however, the European authorities finally decide to define release liner as packaging waste, Erkki Nyberg pointed out, there will be no question: the industry as a whole will have to recycle. Voluntary action is preferable, so Mike Fairley urged: ‘let’s set targets NOW!’

Alternative scenarios

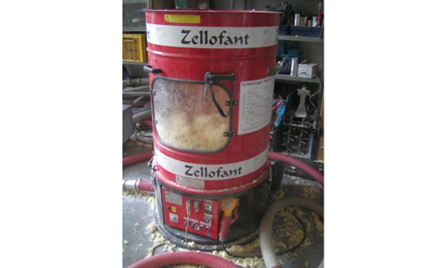

Options other than recycling are also practical in the context of the ‘three Rs’ –reduce, re-use, recycle. Calvin Frost provided an excellent example as to how liner simply can be rewound into rolls, is already being used by small laminators in the Asia Pacific region, for example in making self-adhesive tapes. RecuLiner patented technology is another possible route. Eric van Pottelbergh’s company’s model – already up and running in the Benelux countries -- collects and transforms spent paper release liner into high-performance cellulose fibre insulation material for the construction industry.

The label converters’ role

The label converters are perhaps the key to success in engaging the ‘buy in’ of the end users, since they talk to their customers every day, said Stephan Reis. However, Petri Tani showed that ‘it’s not so easy for a label printer to talk to the right person – who is most probably NOT the person who actually purchases labels.’ The outcome of TLMI’s current pilot spent liner collection initiative with LIFE-registered converters, across seven states, will certainly be of relevance and interest in Europe, and in the broader L9 associations. This provoked a printer delegate to comment that his company had actually been required by one brand owner to sign a form confirming that their labels had NO recycled content.

FINAT: the action hub

As the discussions drew to a close, panelists and delegates agreed on one key future action: it is FINAT, the European label industry’s association, which must take the lead, and ensure that self-adhesive labelling’s future is safeguarded by delivering the message that release liner, paper and film, has a valuable second life after it has performed the tasks in production and application that have made the self-adhesive label such a successful and enduring element of the packaging industry.

Comments

Post a Comment