UK manufacturers, Edale, today announce the installation of their biggest ever order – a 430mm wide 14 colour Card Line machine to an undisclosed company based in Africa, for the production of pre-paid telecom recharge cards.

The unnamed high security printer found that as their business continued to grow their existing sheetfed machines were no longer commercially viable, and they got in touch with Edale for a cost effective solution.

Together, the two companies spent a year researching products, visiting existing Edale customers and developing and testing equipment to ensure that they had a specification tailored to their exact requirements, and December 2014 saw them take ownership of their 14C hybrid flexo/digital/screen Card Line with a wide range of additional options.

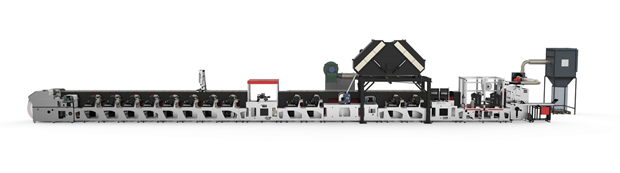

The Card Line boasts 14 UV Flexo heads, Domino K600i for variable printing and verification of variable data (PIN numbers), scratch off verification with G series void marking, alongside a screen unit for application of the scratch off inks and two die units; with the machine measuring an impressive 30m long.

Productivity and flexibility are achieved by combining ‘traditional’ multi-stage manufacturing processes into a single modular machine solution, whilst having the capability to produce all conceivable formats of single and multi-pin cards; this single pass machine has been designed to produce up to 1.5million pins per hour. Combining processes streamlines production, eliminates work in progress and increases the security and traceability of the cards.

Bernhard Grob, Export Sales Director of Edale says “We were delighted to receive this order. Our focus is on the design and engineering of products that are more efficient than current methods or equivalent technologies. This press certainly showcases some fantastic next generation technology and with the quantities this company are producing, they will soon see return on their initial investment”.

CEO of the unnamed company comments “This press allows us to better serve our customers by utilizing new capabilities and services that go beyond what we could previously offer. Our traditional sheetfed production was no longer commercially viable, and flexo will be a lot more cost efficient for us” he continues, “by purchasing a proven technology with a guarantee of machine quality from a British manufacturer gives us great peace of mind”.

The newly installed flexo press offers several advantages over traditional presses, including minimal ink usage and reduced waste to support environmental considerations, while the fast make-ready times enhance productivity rates whilst incorporating lean manufacturing principles.

As well as running scratch card production, the unnamed company also have the ability to configure the machine for the printing and converting of other commercial security applications such as certificates and tax stamps.

James Boughton, Edale’s Managing Director states “The installation of this Card Line illustrates the high security of the Edale personalisation lines and the latest flexo technology available, eliminating outsourcing and providing our customers with a turnkey service; shortened cycle time, and enhanced quality levels on specialised applications,” Boughton continues “Being modular in construction means the company have a lot of scope for adding more diverse application options should they wish to in the future"

Two Edale engineers installed the 14 colour Card Line whilst experienced scratch card instructors were brought in for an additional couple of weeks to train the in-house machine operators.

Edale’s offering is a ‘turnkey’ solution that not only provides the capital equipment but also a high level of consultative support, training and consumables. Edale provides all necessary elements to allow customers production to run as smoothly, and as quickly as possible; from the initial consultation, assistance with applications, process development, full validation and integration of the chosen system to identification and recommendations of consumables, process improvement, support, aftercare and maintenance.

Comments

Post a Comment