Asahi Photoproducts, a pioneer in flexographic photopolymer plate development, will be exhibiting at Converflex 2015, taking place from 19-23 May in Milan. Asahi will be located on stand R20 in hall 2 at the show. Asahi will be featuring its Pinning Top Dot plate technology, which enables a broad colour gamut, vibrant colour reproductions, soft tonal shades and improved productivity.

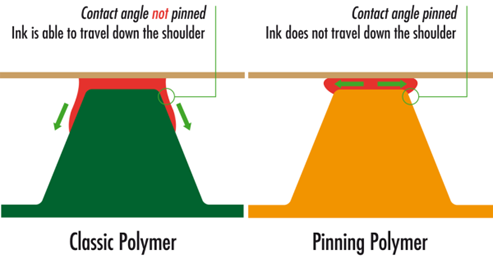

· Comparison classic polymer plates vs. Pinning Top Dot technology from Asahi Photoproducts

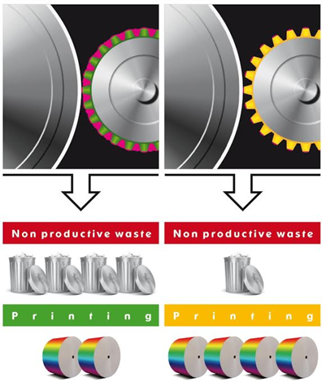

Comparison under printing pressure classic polymer plates vs. Pinning Top Dot technology from Asahi Photoproducts

“We are excited to be attending Converflex 2015,” says Andrea Belloli, Italian branch manager for Asahi. “Initial feedback to our Pinning Top Dot technology, which was announced last year, has been extremely positive and we are looking forward to sharing its benefits with attendees at the show.”

David Galton, UK Sales Director for Asahi Photoproducts, adds, “Converflex is an excellent platform for showcasing Pinning Top Dot technology. The print quality achieved by combining our plate technology with fixed colour palette printing techniques brings outstanding shelf appeal to packaging. Print consistency is crucial to brands’ ability to drive sales volumes by increasing visibility, reinforcing identity and ensuring volume turnover. Pinning Top Dot was designed to improve the quality of the emerging fixed colour palette printing technique, which delivers cost benefits to the brand owner without any compromise in quality. Excellent results have been achieved by working collaboratively with creative agencies, brand owners and printers to take advantage of these unique capabilities, and show attendees will be able to see the results first hand.”

Pinning Top Dot: The Details

A feature of both Asahi’s solvent-washable TOP and water-washable AWP plates, Pinning Top Dot technology (PDT) enables a clean ink transfer and prevents ink accumulating on the plate

surfaces and shoulders in screen areas. This leads to fewer cleaning intervals and reduced downtime, as well as significant quality improvements.

· Waste and printed material yield of classic polymer plates vs. Pinning Top Dot technology

Pinning Dot Technology allows a kiss-touch printing pressure setting. It makes use of low plate surface tension, made possible by a specially engineered Asahi polymer chemistry, to inhibit liquid flow. The ink forms a globule, with a large contact angle and high pinning point. This results in a cleaner and homogeneous ink transfer from plate to substrate, helping flexographic printers meet the ever increasing quality demands of their customers.

Global Debut of HybridA Resin

In addition to its Pinning Top Dot plate lines, Asahi will also debut its new HybridA liquid polymer resin. HybridA resin features higher viscosity for the post-printed corrugated printing market. The resin is a hybrid solution that combines the advantages of liquid resin with the technical properties of a solid plate.

Belloli adds, “Asahi first brought innovative liquid resin technology to market more than 40 years ago, and we are proud that the innovation continues today. This latest liquid resin offering will help customers maintain a leadership position in the highly competitive corrugated market. Both HybridA and Pinning Top Dot technologies will be key elements to our market and we are pleased to be bringing these to Converflex 2015!”

For more information about Pinning Top Dot and HybridA technologies as well as other flexographic solutions from Asahi Photoproducts Europe, visit www.asahi-photoproducts.com.

Comments

Post a Comment